Understanding Industrial XR Training

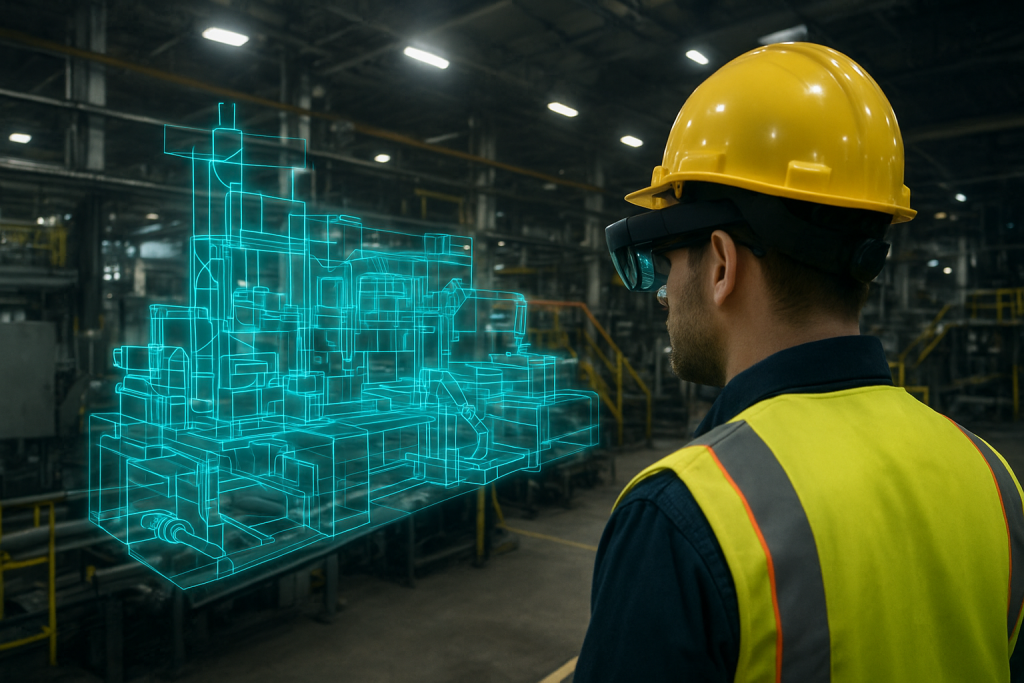

Industrial XR training has become a vital tool for companies moving toward digital transformation. As organizations upgrade their training methods, XR—short for Extended Reality—plays a key role in shaping how employees learn complex tasks. XR includes Virtual Reality (VR), Augmented Reality (AR), and Mixed Reality (MR). Together, they create immersive environments where workers can safely train, practice, and master skills.

Workers can now walk through digital factories, practice hazardous procedures, and handle equipment using lifelike simulations. No real-world risks. No shutdowns. No expensive trial-and-error. Industries that once relied solely on hands-on instruction now use XR to create consistent, measurable, and highly interactive training experiences. This is why the demand for industrial XR training has grown so quickly in recent years.

What Is Industrial XR Training?

Industrial XR training integrates digital simulations into workforce development. It enables workers to train in virtual versions of their actual workspaces. In VR, employees enter a fully immersive environment. With AR, information overlays appear on real-world machines. MR combines both, allowing users to interact with physical and digital objects at the same time.

Evolution of XR in Industrial Sectors

Originally used mainly in gaming, XR technologies slowly made their way into industrial sectors around 2015. Early adopters included aerospace and oil and gas companies that required high-precision workforce training. Over the last decade, lighter headsets, AI-driven content creation, and improved graphics have made XR accessible to factories, warehouses, utilities, automotive plants, and logistics hubs worldwide.

How Industrial XR Training Works in Real Environments

Components of XR Systems

To deliver effective industrial XR training, systems typically include:

- Headsets: VR, AR, or MR goggles with wide fields of view

- Motion tracking sensors: Used for hand, body, and tool interactions

- Spatial mapping technology: Recreates physical environments digitally

- 3D digital twins: Life-like replicas of machines and facilities

- Training software modules: Step-by-step lessons for each skill

- Analytics dashboards: Track training time, accuracy, and performance

- Cloud storage: Saves trainee progress and updates modules automatically

Together, these elements create a stable, repeatable environment for learning.

Workflow of XR-Based Skill Development

Industrial XR training typically follows a structured workflow:

- Launch the training module tied to a specific task.

- Load the virtual environment, modeled after the real workspace.

- Interact using controllers, hand tracking, or voice commands.

- Follow instructions, safety steps, or maintenance procedures.

- Receive instant feedback when errors occur.

- Repeat until mastery, guided by performance analytics.

This streamlined process ensures all workers receive consistent instruction, regardless of trainer availability.

Key Benefits of Industrial XR Training

Improved Safety Outcomes

Safety is one of the most crucial advantages of industrial XR training. In fields such as mining, oil and gas, railways, aviation, or chemical production, mistakes can lead to severe injury, equipment damage, or costly shutdowns. Traditional training exposes trainees to real working hazards during learning. XR eliminates these dangers entirely.

Through fully immersive simulations, workers practice hazardous procedures in a controlled environment. They can rehearse high-risk tasks like handling pressurized systems, performing electrical lockout-tagout, responding to chemical leaks, or navigating confined spaces. Since everything is simulated, trainees can fail repeatedly without consequences. This builds confidence and competence long before they interact with actual equipment.

Another major benefit is standardized safety training. Every trainee experiences the exact same steps, scenarios, and safety prompts. Unlike human instructors—who may vary in training style—XR training ensures the message is always consistent. As a result, companies reduce the chance of human error, miscommunication, or incomplete instructions.

XR also improves emergency preparedness. Workers can train in scenarios that are impossible or dangerous to recreate in real life, such as explosions, fires, or machinery malfunctions. Repeated exposure to emergency simulations increases muscle memory and enhances reaction times. This creates a workforce that responds faster and more accurately in real emergencies.

Finally, XR-based safety training contributes to compliance. Companies can track employee progress, verify completion of required modules, and maintain digital records for audits. By reducing injuries, downtime, and insurance claims, industrial XR training becomes not just a safety tool—but a major cost saver.

Industrial XR Training Applications Across Industries

Manufacturing & Assembly

In manufacturing, XR helps workers practice precision tasks like assembly, welding, and machine setup. Digital twins allow trainees to explore factory layouts, perform part installations, and troubleshoot common issues without halting production. New hires can start training before their first day on the shop floor.

Oil, Gas & Mining

These industries face some of the most dangerous work conditions. XR simulations train workers in:

- pipeline inspection

- rig maintenance

- heavy equipment operation

- dangerous materials handling

Workers gain hands-on experience without facing real hazards.

Aviation & Transportation

Aircraft maintenance is extremely complex. XR allows technicians to visualize aircraft structures, practice component replacements, and simulate inspection procedures. This reduces errors and shortens maintenance cycles.

Energy & Utilities

Technicians can train for electrical grid repairs, power station operations, and wind turbine servicing. XR overlays instructions directly onto real-world equipment, making complex tasks easier to understand.

Challenges in Implementing Industrial XR Training

Hardware & Integration Costs

XR headsets, content creation, sensors, and system integration require upfront investment. However, most companies recoup costs through reduced training hours, fewer mistakes, and improved safety outcomes.

User Resistance & Learning Curves

Some employees—especially those unfamiliar with digital tools—hesitate to adopt XR. Companies overcome this by offering orientation sessions, intuitive user interfaces, and short introductory modules.

Best Practices for Deploying Industrial XR Training

Aligning XR Modules With Job Competencies

Effective training programs focus on real job tasks. Each XR module should tie directly to a measurable competency such as:

- equipment startup

- safety protocol execution

- assembly sequence mastery

Establishing Feedback Loops & Analytics

Dashboards allow employers to track:

- task completion times

- error rates

- number of attempts

- specific steps causing confusion

This data helps improve training content and identify skill gaps.

Choosing the Right XR Hardware

When selecting XR devices, companies must consider:

- field of view

- comfort and durability

- battery life

- compatibility with gloves or protective gear

- software ecosystem support

Future Trends in Industrial XR Training

AI-Driven Content Generation

AI will soon generate XR training modules automatically based on machine manuals, safety protocols, or equipment specs. This will drastically speed up content creation.

Digital Twins & Real-Time Data Sync

Next-generation industrial XR training will connect to IoT sensors, allowing virtual environments to update dynamically:

- machine temperature

- real-time component status

- predictive maintenance alerts

This creates a powerful hybrid between training and live operations.

FAQs About Industrial XR Training

1. Is industrial XR training expensive?

Initial costs can be high, but companies typically save money through reduced errors, fewer injuries, and faster onboarding.

2. Do trainees need technical experience?

No. XR training systems are built for beginners and use intuitive interfaces.

3. Can XR completely replace hands-on training?

Not entirely. XR enhances hands-on training and prepares workers more thoroughly for real tasks.

4. How fast can XR be deployed in a company?

Implementation ranges from weeks to several months depending on complexity.

5. Which industries benefit most from XR training?

Manufacturing, oil and gas, aviation, utilities, and logistics gain the most value.

6. Is XR safe to use for long periods?

Yes, as long as headsets are cleaned and breaks are included during long sessions.

Conclusion

Industrial XR training is reshaping the future of workforce development. It improves safety, speeds up learning, reduces costs, and offers consistent, highly engaging training experiences. Whether used for onboarding, equipment maintenance, emergency response, or routine operations, XR brings tremendous value to modern industrial environments. With the rise of AI and digital twins, XR will only become more intelligent, more accessible, and more essential in the years ahead.

For further reading on industrial tech innovations, visit:

👉 https://www.engineering.com

Looking to deliver training that’s safer, faster, and more efficient for your industrial teams?

Cebirra provides cutting-edge XR Training technology designed for modern industries—complete with realistic simulations, digital twins, and data-driven analytics.

👉 Transform the way your workforce learns and performs.

👉 Reduce risks, cut costs, and boost productivity with immersive XR experiences.

📞 Contact Cebirra today to request a free demo and discover a customized XR training solution tailored to your company’s needs.